In doing so, we have developed a range of products which offer real and tangible gains in supporting the composites industry’s route to net zero. Coupled with a fundamental ethos where service, quality and innovation are at the core of daily activity, sustainability will continue to influence all future product developments.

Our enhanced sustainability product range has applications in all our key sectors including Aerospace, Automotive, Motorsport, Marine and Sporting goods. All products available with a wide array of reinforcement types to match specific performance needs with a specific focus on natural fibres. Below is a quick guide to our bio-content resin systems and natural fibre options.

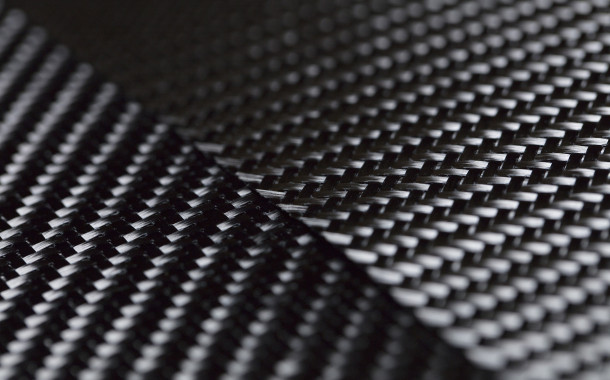

We offer a wide range of tooling and component prepregs suitable for autoclave, press and oven curing. Using our product selector guide you can browse our products by process, type, resin system and market to find the right product for your needs.

Leave your details and we will contact you ASAP