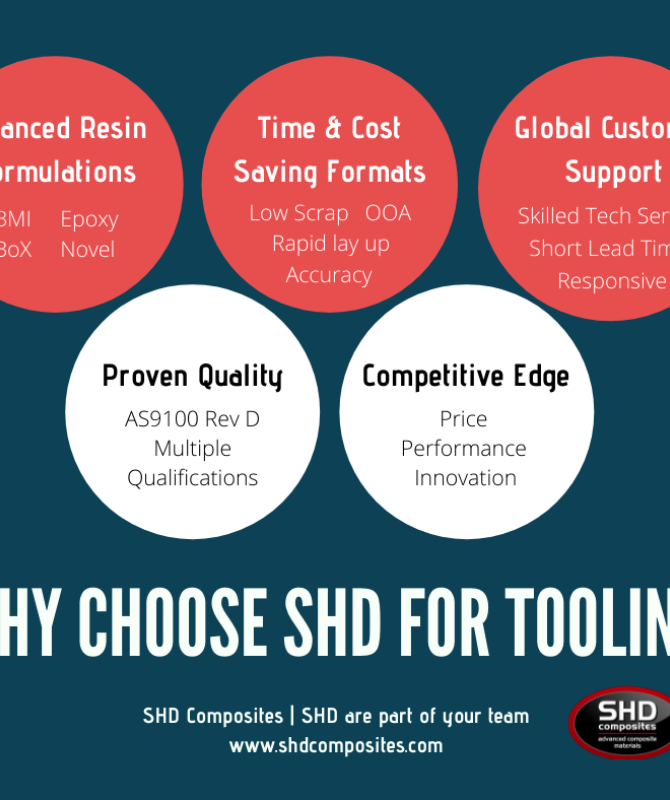

SHD's fundamental ethos is one with service, quality and innovation remaining at the core of daily activity, underpinned by a constant focus on short lead times and market leading customer support.

SHD has been an established market leader in the supply of tooling materials across global Industrial and Aerospace customers for over 10 years.

New Capability! Tooling squares now available in UK from our cutting table on-site. Read more here. Contact us for more information.

We offer a wide range of tooling and component prepregs suitable for autoclave, press and oven curing. Using our product selector guide you can browse our products by process, type, resin system and market to find the right product for your needs.

Leave your details and we will contact you ASAP