BRUCE & WALKER

Bruce & Walker is a small, family business, making hand built carbon fibre fishing rods. The company have been building fishing rods in the village of Upwood, Cambridgeshire, since 1974. Originally using fibre glass, they moved to carbon fibre in the Spring of 1974.

Our relationship in their words…

We were recommended to contact SHD Composite for our carbon fibre material because we were told that they were very happy to deal with smaller businesses. They are a husband and wife business, with a long history of working in the carbon fibre industry. We were told that SHD had grown considerably over the years and were now a very large company, but they still maintained their original ethos, and this appealed to us enormously. We were told that SHD were happy to deal with small companies, such as ourselves, and happy to accommodate our more modest sized orders.

From the very first phone call to SHD, we were made to feel welcome. Such a refreshing change from the mainstream carbon industry! Within 48hrs, their Sales Manager, Glenn, had driven down to meet us. He knew exactly what we were talking about and worked through our process of manufacturing, to see what requirements we needed. He made some very helpful suggestions and by the end of the week, we had placed our first order with them. Everything went smoothly. Nothing was too much trouble.

Although we are very aware that we are a very tiny customer to SHD, we are never made to feel anything but enormously valued and welcome.

The Bruce and Walker process…

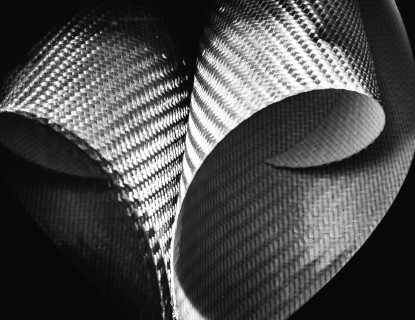

Every rod we make in our workshop, is made to order. And every single one, is different from another. They are all made with the best, high quality carbon fibre. We make different actions of rods, by using exclusively one type of carbon, or by mixing different amounts of different carbons, with various tapers and on various mandrals. We currently have a “standard” range of 140 different models, with different actions. Which is a vast range for a small company! But it is the diversification and the individual nature of our work, which drives the business. We are not a mass production factory. And we never have been. We have always rolled our own blanks, and made our own rods, and this is quite unique in Britain today.

When we collect our new order of carbon, it is immediately put into our freezer. When required, it is removed, cut to length and returned to the freezer straight away. The carbon is cut accordingly to the various lengths required to make up a top section, middle section and butt section of a three piece fishing rod. It is then attached to the specific steel mandral for that rod section, and “rolled” onto the mandral. The part then goes through a taping machine, to tape and hold the carbon onto the mandra. It then goes into the oven for curing.

The carbon “blank” is then extracted from the steel mandral and the “blank” section then has to have the taping removed by hand. Even though the tape is removed, it still leaves a mark in the carbon, so the blank is then linished to give it a smooth appearance, ready for painting or building.

The blank top is fitted to the blank middle and to the blank butt section. When all are fitting correctly, the building work can begin! First of all, we build the cork handle and reel fitting onto the butt section. Then it goes through for painting. This is all done by hand and not sprayed on. Most blanks will have two coats, depending on the rod colour. If the customer has chosen a lighter colour, it will have to have a white undercoat, followed up to three top colour coats.

When the paint is dry, it then goes through to the Finishing Section. Here the rings are whipped on by hand with thread, and each whipping is hand tipped in silver or gold thread, again by hand. Most sections will have between 4-6 rings. Each ring whipping is then varnished. We use three coats of varnish to provide total strength and protection to the whippings. The name of the rod is then either written on by hand, or put on with a transfer – according to the choice of the customer.

We then sew a matching colour rod bag for the rod, and make our own aluminium rod tubes, painted in a matching colour as well. This provides a beautiful package for the rod and complements the rod itself. The rod is either collected by the customer in person, or it is sent by courier.

We also have a very busy Repair Department. At any one time, there will be approximately 20-30 repairs going through the workshop. We can repair any carbon fibre rod, even if it has been discontinued some 30+ years. And many fall into that category. We can make replacement sections for any of our carbon fibre rods. It is this continuity of service that our customers find very attractive. At that same time, many customers return their rods to us for part or full refurbishment at the end of each season. Some rods can have a very busy and tough life. And it is our pleasure to restore them back to full working order and sprinkle a little magic dust on them too!