We supply a full range of SHD component and tooling prepregs engineered for autoclave, press and oven processing, tailored for the requirements of US aerospace, automotive, marine, motorsport and industrial applications.

Our two-site manufacturing model provides resilience, continuity of supply and short lead times, while our experienced technical team offers hands-on support from development through production.

We offer a wide range of tooling and component prepregs suitable for autoclave, press and oven curing. Using our product selector guide you can browse our products by process, type, resin system and market to find the right product for your needs.

Supported by EN 9100-aligned quality and the global SHD Group, we help North American manufacturers accelerate production and deliver consistent, high-performance composite solutions.

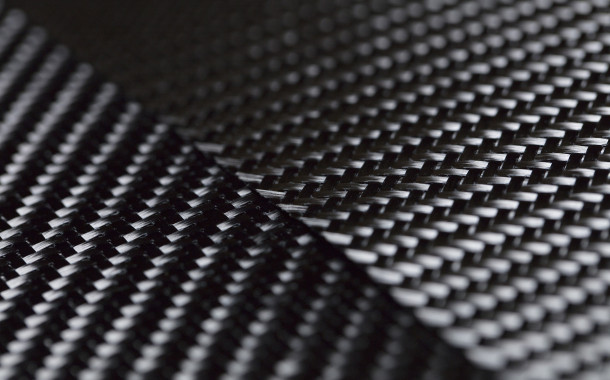

We produce a full suite of high-performance prepregs built for demanding composite structures. We offer carbon, glass and natural-fibre reinforcement options combined with a range of resin systems, enabling precise performance selection for your application.

Designed for autoclave, press and oven curing, our prepregs deliver predictable processing and mechanical consistency across structural components, lightweight assemblies and complex geometries.

We manufacture tooling prepregs engineered for accuracy, stability and clean processing across repeated moulding cycles. These systems support high-precision tooling for aerospace, industrial and automotive applications, offering excellent surface finish and dimensional integrity.

Sustainable manufacturing is becoming a critical priority across US industries. SHD’s bio-based composite materials offer a practical, lower-impact alternative to traditional systems while maintaining the performance and processing behavior manufacturers expect.

These materials integrate easily into existing workflows and support organizations aiming to reduce environmental impact without compromising part quality.

Our materials are used widely across the American aerospace, automotive, motorsport, marine, rail and industrial sectors.

Each industry brings different performance, regulatory and production pressures, and our team provides tailored guidance to ensure the right material solution for each application - from high-temperature structures to rapid-turnaround performance parts or durable industrial components.

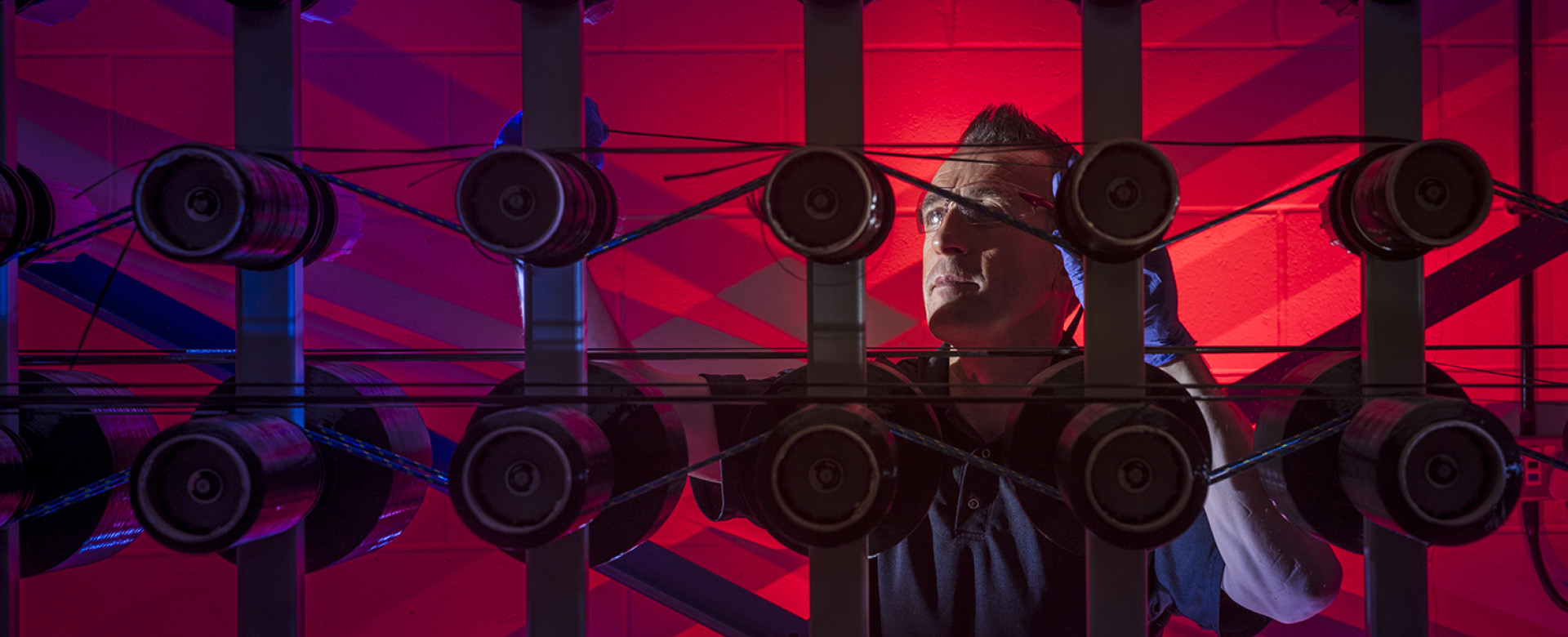

We provide direct access to expert technical guidance and collaborative development support.

We work closely with engineers, production teams and R&D groups to refine material selection, optimize cure cycles, enhance processing efficiency and support qualification.

This partnership-driven approach helps reduce risk, shorten development time and ensure consistent, reliable performance at scale.

Fill in this short contact form and a member of staff will be in touch as soon as possible. Alternatively if you’d like to speak to someone on the phone please see details below.

For credit issues and remittances, please email us-sales@shdcomposites.com

Leave your details and we will contact you ASAP