We work closely with our customers to provide the right product for every application, by offering technical support and expertise before, during and after product usage.

With a technical center housing a test laboratory and autoclave, we can ensure that this commitment is taken to the next level. Not only working to continually improve our existing range of products, we work to develop new and exciting products through our recognition of an industry need, and through project consortiums.

Multiple frames up to 250kN with various fixtures for static testing (tension, compression, shear, etc.) and with a climatic chamber for elevated and sub-ambient temperatures.

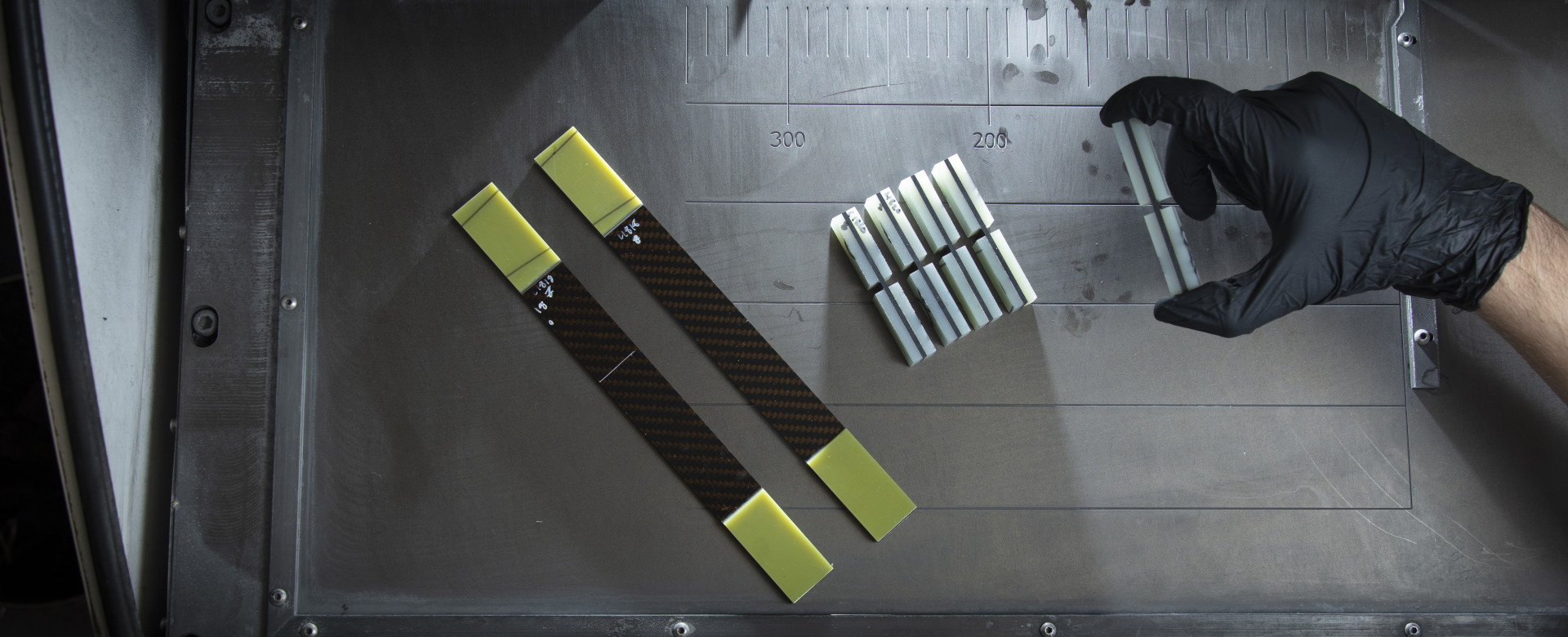

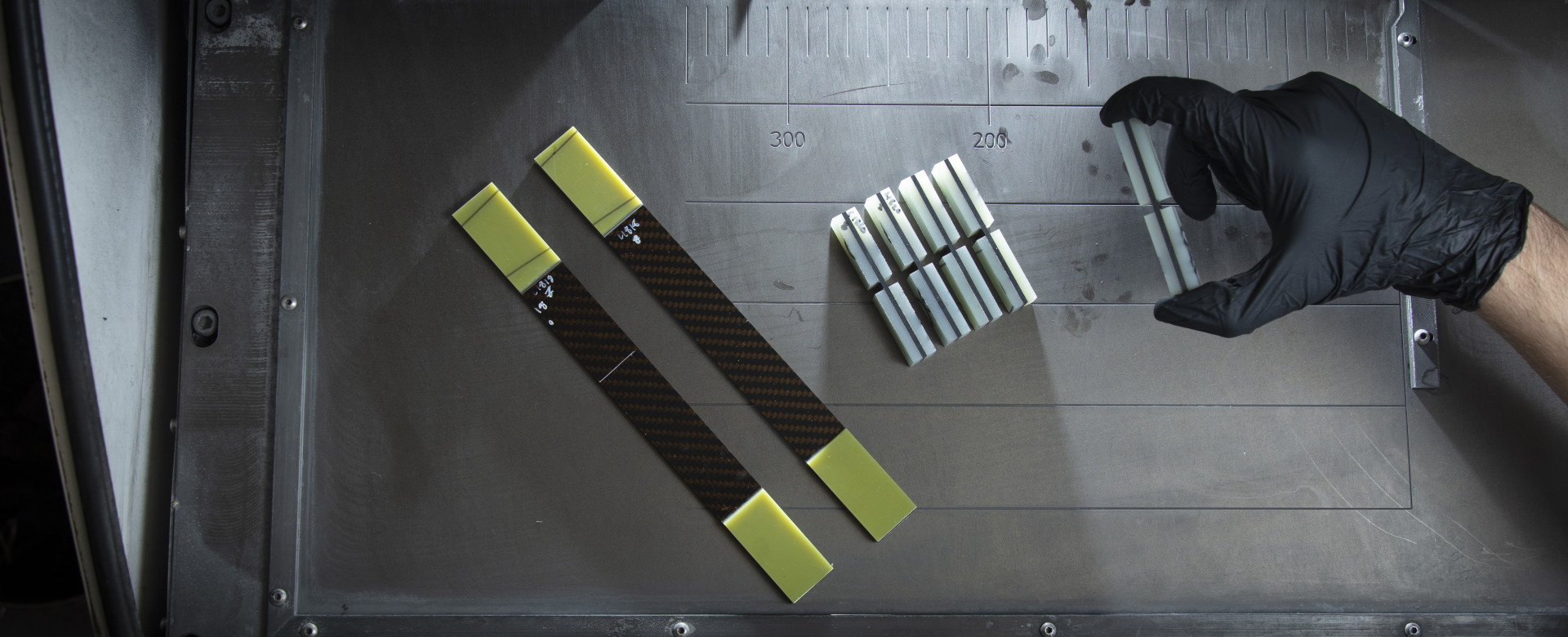

Conversion of composite panels into test specimens (cutting, surface preparation and bonding) with high accuracy tools, to the tight tolerances required for mechanical characterisation.

DSC (Differential Scanning Calorimetry), DMA (Dynamic Mechanical Analysis), TMA (Thermo-Mechanical Analysis).

Rotational rheometer.

UV & humidity chamber.

FTIR (Fourier Transform Infrared Spectroscopy) with ATR (Attenuated Total Reflectance) cell.

Low Cost FST Compliant Composite Components (NATEP)

LCHPT: Lower Cost, Higher Performance, Composite tooling (NATEP)

Pivot into Space is an R&D programme designed to support small innovative engineering companies cross the Midlands to pivot their technologies and capabilities into the UK’s growing space markets.

Leave your details and we will contact you ASAP